Christmas is now over and I have successfully defeated the dreaded man flu so it's all systems go!

Back in the workshop today to prepare ready for joining the wings together, either later tonight or tomorrow.

Updates to follow.

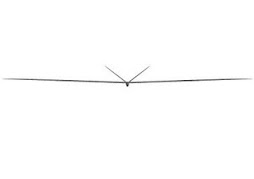

F3B.

Wednesday 30 December 2009

Sunday 13 December 2009

More Tailplane Pictures

Saturday 12 December 2009

Good Tailplane!!

A good result and probably the best tailplane yet, the weight is the lightest so far without any detriment to the strength, the major weight saving has been both the paint and epoxy.

The yellow paint is very opaque so it will be interesting to see the wings when they are joined next week.

I should receive delivery of the new disser tissue next Wednesday so a test tailplane will be made over the Christmas break before the next whole model is laid up.

Any comments welcome please?

Harry.

The yellow paint is very opaque so it will be interesting to see the wings when they are joined next week.

I should receive delivery of the new disser tissue next Wednesday so a test tailplane will be made over the Christmas break before the next whole model is laid up.

Any comments welcome please?

Harry.

Foam core joiner

Friday 11 December 2009

One In The Oven!

I managed to join the tailplane this evening, thanks for the nuts Mikey!

As you can see from the photos below the dry spars weigh just 10g, these were wet out and then dabbed with blue roll to take off all the excess resin. A small bead of epoxy/cotton flock/micro balloon mix was piped around the edges.

Should be ready to open the moulds tomorrow, update to follow.... right now I'm going out to collect a Chinese banquet and bottle of the good stuff with the lovely Mrs H.

Take care for now.

As you can see from the photos below the dry spars weigh just 10g, these were wet out and then dabbed with blue roll to take off all the excess resin. A small bead of epoxy/cotton flock/micro balloon mix was piped around the edges.

Should be ready to open the moulds tomorrow, update to follow.... right now I'm going out to collect a Chinese banquet and bottle of the good stuff with the lovely Mrs H.

Take care for now.

Tuesday 8 December 2009

New joiner and fus layup results

Good news all parts are keepers. Slight problem getting silicone cores out of joiner, they broke off about 10mm in from the end so they will be staying in this one, this is a shame because the moulding is the best joiner I have made yet.

The fus has come out well although still some cosmetic issues around the wing seat. New lay up idea to increase hoop strength has worked really well, not too easy to see on the photo but you can just make out the band of additional twill weave cloth. In the flesh I am please to say it looks "well Trick"

Harry all I need now is a set of wings and a tailplane.

Hope all out there are enjoying the read, feed back it welcome and if anyone can give me any pointers on how to make hollow joiner I would be great full.

The fus has come out well although still some cosmetic issues around the wing seat. New lay up idea to increase hoop strength has worked really well, not too easy to see on the photo but you can just make out the band of additional twill weave cloth. In the flesh I am please to say it looks "well Trick"

Harry all I need now is a set of wings and a tailplane.

Hope all out there are enjoying the read, feed back it welcome and if anyone can give me any pointers on how to make hollow joiner I would be great full.

Monday 7 December 2009

iPhone test

Sunday 6 December 2009

Another weekend another fus

Just finished putting a fus, joiner box, ballast tube, nose cone and joiner in the oven at the High Peak Zenith factory. Tried something new on the joiner, use two silicone strips as the internal cores instead of the usual foam, I hope to remove these after curing to leave hollows. Also tried a slightly different layup of the fus around the wing seat and added some more hoop strength go the fus behind the wing, if nothing else it will certainly look different. Hope to turn the oven on tomorrow night so I should have parts to look at on Tuesday. Sorry no photos didn't get around to that today.

Pre Joining Work

Pre joining work is completed on the tailplane, they would have gone together today but frustratingly I have ran out of M3 captive nuts.......AAAHHHHH!

Not all bad news, this small set back has given me the head start on the pre joining work of the wings, all the shear webs are ready and lined up with the new joiner boxes. My new servos arrived Saturday morning courtesy of Phoenix models, I only ordered them at 4pm on Friday, fantastic service and at only £32.50 each this is a saving of about £5 against other suppliers, they are also getting a stock of Schulze receivers so this will be a one stop shop for me!

The servos are being moulded into the wing to increase the aerodynamic efficiency of the bottom wing surface as there will be no taped hatch. This will also decrease the amount of finishing work when the model is de-mouded, good news! We will eventually go the RDS route but for now we just want to get some models together for the 2010 season.

Anyway......I will order the M3 captive nuts tomorrow and will update soon.

Take take for now, Harry.

Not all bad news, this small set back has given me the head start on the pre joining work of the wings, all the shear webs are ready and lined up with the new joiner boxes. My new servos arrived Saturday morning courtesy of Phoenix models, I only ordered them at 4pm on Friday, fantastic service and at only £32.50 each this is a saving of about £5 against other suppliers, they are also getting a stock of Schulze receivers so this will be a one stop shop for me!

The servos are being moulded into the wing to increase the aerodynamic efficiency of the bottom wing surface as there will be no taped hatch. This will also decrease the amount of finishing work when the model is de-mouded, good news! We will eventually go the RDS route but for now we just want to get some models together for the 2010 season.

Anyway......I will order the M3 captive nuts tomorrow and will update soon.

Take take for now, Harry.

Subscribe to:

Posts (Atom)